Primalcom Port Terminal Operating System

Primalcom’s Port Terminal Operating System (STOS) is a comprehensive solution designed to streamline and optimize the complex operations of modern seaports. The system integrates multiple facets of seaport management, ensuring efficient operations, improved productivity, and enhanced customer satisfaction.

Terminal Operating System Modules

Integrated Seaport Management involves the coordination of various operations within a seaport to ensure seamless functionality. Primalcom’s port terminal operating system provides a centralized platform for managing all activities, including vessel scheduling, berth allocation, and resource management. The integration of this system facilitates real-time data sharing among departments, leading to better decision-making and operational efficiency.

Benefits:

- Enhanced coordination between different port operations

- Real-time tracking and monitoring of port activities

- Improved resource utilization

- Better compliance with regulatory requirements

Container Terminal Operation and Billing handles the management of container movements and the associated financial transactions. Primalcom’s port terminal operating system offers robust features for tracking container locations, managing inventory, and automating billing processes.

Features:

- Real-time tracking of container movements

- Automated billing and invoicing

- Integration with shipping lines and freight forwarders

- Detailed reporting and analytics

Benefits:

- Reduced manual errors and paperwork

- Faster turnaround times for containers

- Enhanced transparency in billing

- Improved customer satisfaction

Multi-Terminal Operation and Billing enables the management of multiple terminals within a seaport under a unified system. Primalcom’s solution supports the coordination of activities across different terminals, ensuring efficient resource allocation and seamless billing processes.

Features:

- Centralized management of multiple terminals

- Unified billing system

- Resource sharing and optimization

- Comprehensive reporting and analytics

Benefits:

- Improved coordination between terminals

- Reduced administrative overhead

- Enhanced operational efficiency

- Better financial management

Gate Automation involves the use of technology to streamline the entry and exit of vehicles and cargo through port gates. Primalcom’s system offers automated gate management solutions that reduce wait times and enhance security.

Features:

- Automated vehicle identification and access control

- Real-time tracking of gate movements

- Integration with terminal operations

- Detailed logging and reporting

Benefits:

- Reduced congestion at port gates

- Enhanced security and access control

- Faster processing times for vehicles and cargo

- Improved data accuracy and reporting

Container Depot Operation focuses on the efficient management of container storage facilities. Primalcom’s solution provides tools for tracking container conditions, scheduling maintenance, and optimizing storage space.

Features:

- Container condition monitoring

- Automated maintenance scheduling

- Space optimization algorithms

- Integration with terminal operations

Benefits:

- Prolonged container lifespan through timely maintenance

- Efficient use of storage space

- Reduced operational costs

- Better inventory management

Cargo Freight Station (CFS) management involves the handling of cargo before it is loaded onto or after it is unloaded from ships. Primalcom’s system facilitates efficient management of these operations through automation and real-time tracking.

Features:

- Automated cargo handling processes

- Real-time cargo tracking

- Integration with customs and regulatory authorities

- Detailed cargo documentation and reporting

Benefits:

- Faster processing times for cargo

- Reduced risk of cargo damage or loss

- Enhanced compliance with customs regulations

- Improved operational efficiency

Reefer Monitoring focuses on the management and tracking of refrigerated containers to ensure that temperature-sensitive cargo is maintained at optimal conditions. Primalcom’s port terminal operating system provides real-time monitoring and alerting for reefer containers.

Features:

- Real-time temperature monitoring

- Automated alerts for temperature deviations

- Integration with container tracking systems

- Detailed logging and reporting

Benefits:

- Reduced risk of cargo spoilage

- Enhanced compliance with regulatory requirements

- Improved customer satisfaction

- Better inventory management

Common Issues in Seaport Terminals

Seaport terminals frequently handle large volumes of cargo, and without an effective system, this can lead to disorder. Reliance on manual processes and outdated technology can result in delays, mistakes, and congestion within the terminal. Ineffective cargo management diminishes throughput and can disrupt the supply chain, ultimately leading to customer dissatisfaction and financial setbacks.

Many terminals face difficulties in tracking the real-time movement and location of containers and cargo. This lack of visibility complicates the optimization of terminal operations, resulting in lost or misplaced cargo, unutilized yard space, and inefficient workflows. The absence of real-time data also obstructs coordination among terminal operators, shipping lines, customs, and logistics providers.

The management of resources such as cranes, trucks, and labor in a seaport terminal can be highly complex. Without a comprehensive system to monitor and allocate these resources, terminals may experience underutilization of equipment, idle labor, and inefficient yard space usage. This can lead to increased operational expenses and diminished productivity.

Effective communication among stakeholders—including shipping lines, customs authorities, logistics providers, and terminal operators—is essential for seamless operations. Miscommunication or delays in information can result in scheduling conflicts, missed deadlines, and operational disruptions. Additionally, without a centralized platform for coordination, terminals often find it challenging to manage their operations effectively.

The combined impact of these inefficiencies leads to rising operational costs. Delays in cargo management, underutilized resources, and poor workflow management can contribute to higher fuel expenses, increased labor costs, and lost revenue opportunities. These issues ultimately diminish the competitiveness of terminals in a highly competitive global market.

Solutions Offered by Primalcom’s Seaport Terminal Operating System (TOS)

Primalcom’s Seaport TOS streamlines essential cargo management tasks, significantly minimizing the potential for errors and delays. The system enhances the transfer of containers between vessels and the yard, ensuring swift and efficient cargo handling. With real-time updates, terminal operators can proactively plan cargo activities, optimizing throughput and alleviating bottlenecks.

The Seaport TOS features tools for the effective management and optimization of resources such as cranes, trucks, and personnel. By tracking equipment usage and availability in real-time, the system enhances resource allocation and reduces idle time. This results in increased productivity and lower operational costs, as terminals can fully leverage their available resources.

The TOS delivers real-time visibility of containers and cargo, enabling operators to pinpoint the precise location and status of each unit at any moment. This improved tracking facilitates better decision-making and ensures efficient utilization of yard space. By providing accurate and current information, the TOS decreases the likelihood of misplaced cargo and allows for quicker responses to operational shifts or challenges.

Primalcom’s Seaport TOS serves as a centralized hub for all stakeholders to communicate and coordinate their efforts. Shipping lines, customs, and logistics providers can exchange information and collaborate in real-time, minimizing the risk of miscommunication and scheduling conflicts. This level of integration ensures smooth operations with fewer disruptions and delays.

By optimizing terminal operations and enhancing resource allocation, the Seaport TOS aids terminals in lowering their operational expenses. Automation and real-time tracking reduce labor costs, while improved equipment utilization contributes to decreased fuel expenses.

Our Applications Have Served

30+

Ports & Terminals

10+

million TEUs

30+

millions Tonnes of cargo and counting

100+

Quay Cranes

Why Choose Primalcom’s Terminal Operating System?

Primalcom’s Port Terminal Operating System offers a comprehensive suite of advanced tools designed to optimize and streamline seaport operations.

Our solution covers everything from integrated management and container handling to advanced gate automation and reefer monitoring, ensuring that seaports operate efficiently, securely, and profitably. By leveraging cutting-edge technology and real-time data integration, Primalcom enables ports to meet the growing demands of the ever-evolving maritime industry. Whether managing a small or large terminal, our TOS software is engineered to maximize performance and maintain operational efficiency at all times.

With our container terminal operating system, you’ll have full visibility into your operations, allowing you to increase productivity, reduce downtime, and improve turnaround times for vessels.

Reduce manual labor and streamline processes with port automation. Our solution minimizes human errors and ensures that your terminal operates with greater efficiency.

As your terminal grows, so does our system. Primalcom’s terminal operating system vendors ensure that our solution is fully customizable and scalable to meet the needs of any port, large or small.

Our port management software gives you complete control over port operations, offering real-time data that helps you make informed decisions about cargo handling, container tracking, and vessel berthing.

Overview of the Functionality of PrimalCom's Sea Port Terminal Operating System

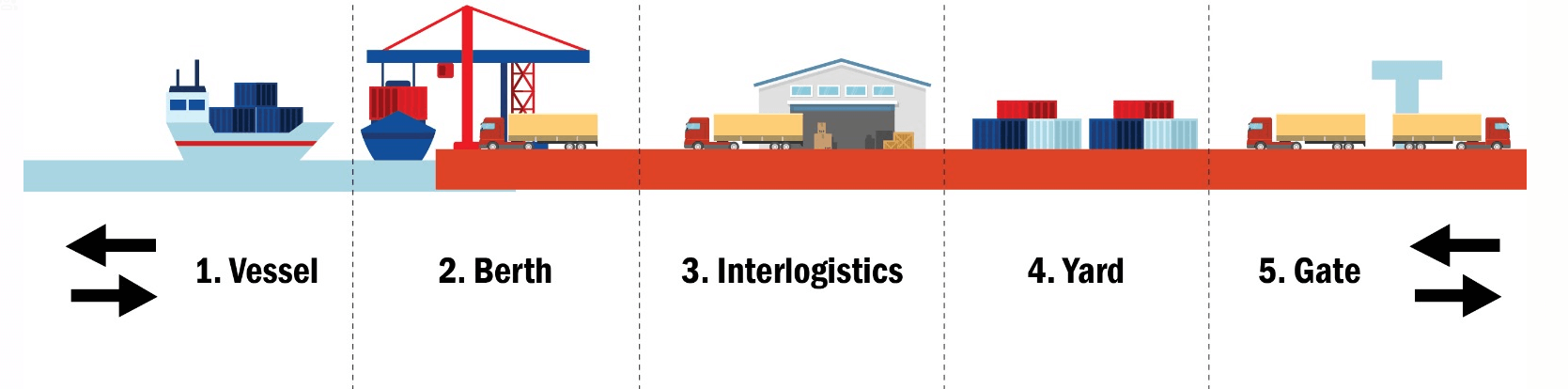

PrimalCom’s Sea Port Terminal Operating System (TOS) is designed to enhance the efficiency of container movement through five essential stages, ensuring a smooth transition from the vessel to the terminal and beyond.

Upon the vessel’s arrival at the port, quay cranes are employed to unload the containers. The system effectively manages crane scheduling and the transfer of containers from the ship to the terminal.

Key Features:

- Real-time monitoring of vessel schedules

- Enhanced crane operations for effective unloading

- Oversight of container placement to facilitate smooth transfers

After unloading, trucks or automated vehicles are responsible for transporting the containers across the terminal to their assigned yard or processing area. PrimalCom’s TOS guarantees that each inbound container is routed to the appropriate location for prompt processing.

Key Features:

- Automated scheduling for transport

- Optimized routing for vehicles to minimize travel duration

- Continuous monitoring and tracking of containers

Once the containers arrive at the inbound yard, yard cranes take over to sort and position them in temporary storage or directly transfer them to their subsequent destinations. Our TOS ensures effective management of inbound containers, thereby reducing delays.

Key Features:

- Intelligent utilization of yard space

- Real-time tracking of container locations

- Integration with automation systems for streamlined handling

In instances where cranes or trucks are not engaged in transporting containers, the TOS orchestrates the empty travel and repositioning of equipment. This approach minimizes idle time and guarantees that vehicles and cranes are optimally situated for their upcoming tasks.

Key Features:

- Decreased idle periods for cranes and vehicles

- Smart repositioning based on operational requirements

- Enhanced utilization of equipment

For outbound containers, yard cranes facilitate the transfer of containers from their storage locations to trucks or rail systems.

Key Operational Areas in a Terminal

Operational Area

This zone is responsible for the transfer of containers from ships to the port. Utilizing state-of-the-art cranes and specialized equipment, this area is the nucleus of port operations, efficiently managing the transfer of thousands of containers with both speed and precision.

Container Yard

Once containers are unloaded, they are stored in the yard for further processing. In this space, forklifts and automated systems manage the distribution of containers to various locations based on logistical demands. Effective management of the container yard is vital to prevent congestion and to ensure that cargo is readily accessible for the next stage of transport.

Landside Operations Area

When containers are prepared for shipment, they are moved to the landside operations area, where they are loaded onto trucks or trains for delivery. The Terminal Operating System (TOS) coordinates these movements to ensure that each container reaches its destination promptly.

Grasping the Fundamental Stages of Port Terminal Operations

Our Sea Port Terminal Operating System encompasses five essential phases in port logistics, guaranteeing the efficient movement of containers and cargo from the vessel to their ultimate destination:

The process initiates with the arrival of a vessel at the port, laden with cargo containers. Our system facilitates real-time monitoring and coordination to enhance docking, cargo transfer, and scheduling. This phase emphasizes precise tracking of incoming cargo, minimizing delays and ensuring the terminal is adequately prepared for operations.

Key Benefits:

- Real-time vessel tracking

- Optimal docking and unloading schedules

- Seamless integration with port authorities

Upon the vessel’s docking at the berth, the unloading of cargo is executed with accuracy. Utilizing cranes and other equipment, containers are transferred to trucks or trailers, primed for the subsequent phase of their journey. Our system guarantees that this process is harmonized to prevent congestion and reduce the time spent at the berth.

Key Benefits:

- Synchronized unloading operations

- Prevention of congestion at the berth

- Integration with automated machinery

During this phase, interlogistics becomes pivotal, as goods are moved from the quay to the warehouse for sorting, inspection, or immediate transfer. Whether the cargo is to be stored or directly dispatched to its next destination, PrimalCom’s TOS ensures that interlogistics processes are efficient, well-coordinated, and traceable.

Key Benefits:

- Efficient warehouse management

- Real-time tracking of cargo movements

- Automated sorting and inspection workflows

Our yard management system oversees the storage and retrieval of containers, ensuring optimal utilization of space within the terminal. The system monitors container movements and provides operators with real-time information regarding the location and status of each container, facilitating effective container management.

Key Benefits:

- Optimal yard space utilization

- Real-time container tracking

- Enhanced operational efficiency

The concluding phase of the terminal process is the gate, where containers exit the port using trucks or rail transport. Our system oversees gate operations, facilitating quick and secure movement of cargo. By implementing automated gate procedures, we minimize wait times, enhance throughput, and guarantee that all security and compliance assessments are smoothly incorporated.

Key Benefits:

- Automated entry and exit procedures at the gate

- Decreased truck dwell times

- Secure compliance verification

How Our TOS Can Transform Your Port

Primalcom’s container terminal operating system is designed to transform how your port operates by automating key tasks, improving container tracking, and offering real-time insights into every stage of the process.

Optimize Yard Management

Use our container depot management system to manage yard space more effectively, reducing congestion and increasing throughput.

Accurate Shipping Container Tracking

Keep track of all shipping containers with our shipping container tracking system, ensuring accurate and timely container movements within your port.

Efficient Cargo Handling

Implement automated cargo handling processes to improve safety, reduce wait times, and ensure efficient cargo flow across your terminal.

Our Focus Industries

Primalcom’s Sea Port & Terminal Operating System is designed to enhance efficiency and streamline operations for various industries, with a focus on:

- Sea Ports and Terminals

- Telecommunications, Oil & Gas

- Banking & Financial Institutions

- Government & Public Sector

- Manufacturing, and Military & Defense

Our innovative solutions optimize cargo handling, vessel scheduling, and resource management, ensuring seamless and secure workflows in high-demand environments. Tailored to meet the specific needs of diverse sectors, our system supports complex logistical operations, improves communication, and enhances data-driven decision-making. Whether it’s enhancing port operations or supporting defense logistics, Primalcom’s robust platform helps businesses and institutions achieve greater productivity, security, and operational excellence.

Frequently Asked Questions

A Terminal Operating System (TOS) is a specialized software solution designed to manage and automate the day-to-day operations of sea ports and container terminals. It helps streamline tasks such as cargo handling, container tracking, vessel scheduling, and overall terminal management to enhance efficiency and reduce manual intervention.

Primalcom’s TOS provides real-time data and automation tools that optimize port operations. It enhances productivity by automating tasks such as container movement, yard management, vessel planning, and cargo tracking. This results in reduced human errors, lower operating costs, and improved turnaround times for vessels.

Yes, our Terminal Operating System includes an integrated container tracking system software that allows for real-time monitoring of containers throughout the terminal. This helps improve efficiency and ensures timely container handling and delivery.

Absolutely. Primalcom’s TOS is scalable and customizable, making it suitable for terminals of any size. Whether you operate a small regional port or a large global terminal, our TOS can be tailored to meet your unique operational requirements.

Our cargo handling system automates the process of loading, unloading, and moving cargo within the terminal. By integrating with cranes, trucks, and yard management systems, the TOS ensures that cargo handling is performed efficiently, with minimal manual input.

Key features of our TOS include:

- Port Automation: Automates key operational tasks such as gate control, vessel scheduling, and container stacking.

- Real-Time Tracking: Tracks the movement of containers in real time within the terminal.

- Freight Terminal Management: Manages freight operations efficiently, from cargo loading to yard allocation.

- Port Management Software: Provides tools for overall port management, including reporting, analytics, and decision-making support.

Yes, by automating many of the manual processes within the terminal, the TOS reduces labor costs and operational inefficiencies. It also improves resource allocation and enhances productivity, leading to overall cost savings for the terminal.

Yes, you can request a free demo of Primalcom’s Terminal Operating System to see how it can transform your port operations. Simply contact us through our website to schedule a demonstration.

Primalcom’s TOS is designed to integrate seamlessly with existing port infrastructure and software. This includes systems such as container depot management, yard management, and crane automation, ensuring smooth and efficient operations.

The implementation process involves a thorough assessment of your terminal’s needs, followed by customization of the software to fit your requirements. Our team provides end-to-end support during installation, integration, and training, ensuring a smooth transition to the new system.

Primalcom provides comprehensive support after the TOS is implemented. This includes system maintenance, troubleshooting, software updates, and ongoing technical support to ensure that your terminal continues to operate smoothly.

Our TOS includes advanced security features such as access control, container identification, and real-time monitoring to ensure that unauthorized access and potential threats are minimized within the terminal. The system also provides audit trails and detailed reporting for enhanced security oversight.

Yes, Primalcom’s TOS is built to handle complex, multi-terminal operations. The system offers centralized management for multiple terminals, allowing for efficient coordination and control across different port facilities.

By automating processes and optimizing resource allocation, Primalcom’s TOS reduces energy consumption and operational waste. This leads to more sustainable port operations, with lower carbon footprints and more efficient use of resources.

Case Studies

01

A major Indonesian container terminal, partnered with Primalcom to implement its Sea Port Terminal Operating System (TOS) to streamline operations and enhance port efficiency.

02

A visionary company focused on digitalization and connectivity, partnered with Primalcom to implement its cloud-based Terminal Operating System (My-TOS) and Foundation & Billing system (My-Bill$).

03

A Digital Twin in the seaport industry is a virtual representation of physical assets, systems, and processes.

Request a Free Demo Today

Discover how Primalcom’s advanced Terminal Operating System (TOS) can revolutionize your sea port terminal operations. Request a free demo today to see how our port management software can increase efficiency, reduce costs, and transform your terminal into a high-performing hub of maritime trade.

Get Started Now and see why ports worldwide trust Primalcom’s TOS software for all their terminal management needs.